I ka hana ʻana i kahi make holomua, ʻo ke kaomi ʻana o ka mea hana, nā kūlana kaomi a me nā mea hoʻomaka e pili i ka hiki ke loaʻa nā hopena kiʻi paʻa me ka ʻole o nā wrinkles.

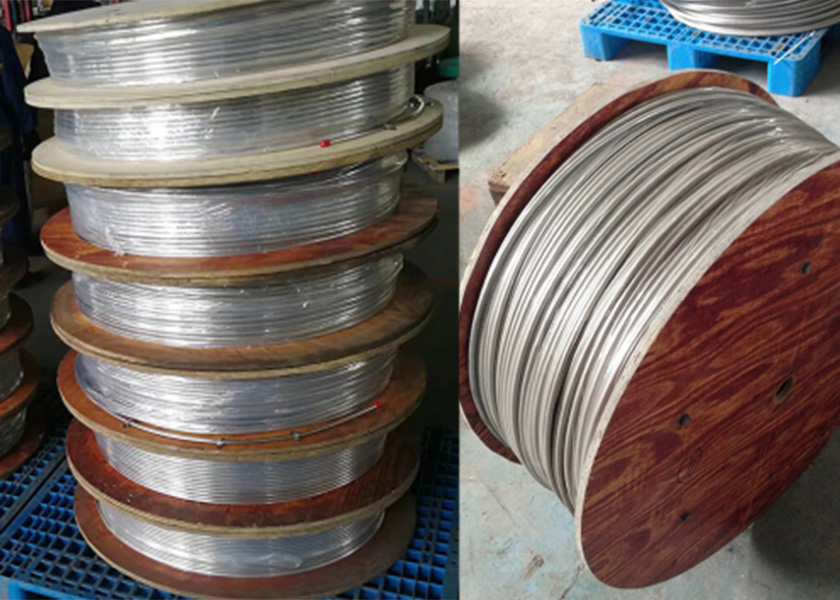

Q: Hana mākou i ke kīʻaha ma 304 stainless steel.Ma ke kahua mua o ka make holomua, huki mākou ma kahi o 0.75 iniha ka hohonu.Ke nānā au i ka mānoanoa o ka ʻaoʻao flange butt, hiki ke hoʻololi i ka 0.003 iniha mai kekahi ʻaoʻao a i kekahi ʻaoʻao.He ʻokoʻa kēlā me kēia pā a ʻaʻole ʻike ʻia ma kahi hoʻokahi.Ua haʻi ʻia iaʻu he mea pili ia i ka hana ʻana i ka mea maka, ʻo ka ʻaoʻao paha o waho o ka spool nui.Pehea e hiki ai iā mākou ke loaʻa i ke kīʻaha o ke ʻano mau me ka ʻole o nā kulu?

A: ʻIke wau he nīnau ʻelua kāu nīnau: ʻo ka mua nā ʻokoʻa āu e loaʻa ai i ke kaʻina hana kiʻi, a ʻo ka lua ke kumu kumu a me kāna kikoʻī.

ʻO ka pilikia mua he hemahema kumu i ka hoʻolālā ʻana o ka mea hana, no laila e hele kāua i nā kumu.ʻO ka wrinkling manawa a me ka loli ʻana o ka mānoanoa ma nā ʻaoʻao kīʻaha ma hope o ka hohola ʻana e hōʻike ana i ka lawa ʻole o nā mea hana hoʻopaʻa i kāu kahua hoʻopololei make holomua.Me ka ʻike ʻole ʻana i kāu hoʻolālā make, pono wau e manaʻo e hoʻokō ka punch a me ka radii make a me ko lākou ʻae ʻana i nā palena hoʻolālā maʻamau.

Ma ke kaʻina hana kiʻi, paʻa ka mea hana ma waena o ke kiʻi kiʻi a me ka mea paʻa i ka ʻaoʻao, ʻoiai e huki ana ke kiʻi kiʻi i ka mea i loko o ka make kiʻi, e huki ana ma ka radius kaha kiʻi e hana i ka pūpū.Loaʻa ka hakakā ikaika ma waena o ka ʻōpala a me ka mea paʻa mea hana.I loko o kēia kaʻina hana, hoʻopili ʻia ka mea i ka transverse compression, ka hopena i ka wrinkling a me ka elongation radial i ka wā e pani ai ka mea paʻa i ke kahe o ka mea.Inā kiʻekiʻe loa ke kaomi hoʻopaʻa ʻana, e haki ka mea ma lalo o ka ikaika huki o ka punch.Inā haʻahaʻa loa, e ʻike ʻia nā wrinkles.

ʻAʻole hiki i ka hana kaha kiʻi holomua ke ʻoi aku ma mua o ka palena ma waena o ke anawaena pūpū a me ke anawaena mea hana.Pili kēia palena i ka pākēneka elongation o ka mea.ʻO ke kānāwai maʻamau e pena i ka 55% a 60% i ka manawa mua a me 20% i kēlā me kēia manawa ma hope o kēlā.Ma ka fig.Hōʻike ka 1 i ke ʻano maʻamau no ka helu ʻana i ke kaomi preform e koi ʻia no ka hoʻolōʻihi ʻana (Hoʻohui mau wau i ka liʻiliʻi o 30% ka ikaika hou ma ke ʻano he kumu palekana. Hiki ke hoʻemi ʻia inā pono, akā paʻakikī ke hoʻonui ma hope o ka pau ʻana o ka hoʻolālā).

ʻO ke kaomi billet p he 2.5 N / mm2 no ke kila, 2.0-2.4 N / mm2 no ke keleawe keleawe a me 1.2-1.5 N / mm2 no ke alumini alumini.

Hiki i nā ʻokoʻa o ka mānoanoa flange ke hōʻike ʻaʻole lawa ka ikaika o kāu hoʻolālā mea hana.Pono ka mānoanoa o ka kāma'a po'o i hiki ke kū'ē i ka ha'alulu me ka piko'ole.ʻO ke kākoʻo ma lalo o ka kāmaʻa he kila ikaika, a ʻo nā pine alakaʻi o nā mea hana pono e lawa ka nui e pale ai i ka neʻe ʻana o ka ʻaoʻao o nā mea hana ma luna a me lalo i ka wā e hoʻolōʻihi ai.

E nānā pū i kāu nūhou.Inā ʻeha a hemo nā alakaʻi paʻi, ʻaʻole ʻoe e kūleʻa, no ka ikaika o kāu mau mea hana.E nānā i ka mea paʻi paʻi e hōʻoia i ka pololei a me ka huinahā i ka lōʻihi o ka paʻi paʻi.E hōʻoia i ka kānana ʻana i kāu lubricant kiʻi kiʻi a me ke kūlana maikaʻi, a ke hoʻohana nei ka mea hana i ka nui kūpono a me ke kūlana nozzle kūpono.Nānā maikaʻi ʻia nā mea paʻi a pau e hōʻoia i ka hoʻopau pono ʻana o ka ʻili, ka uhi a me ka symmetry.A e noʻonoʻo pono i ke kaha ʻana i ka radii, pono lākou i ka geometry kūpono a me ka maʻemaʻe o ka ʻili.

Eia kekahi, ʻoiai ke manaʻo nei nā mea kūʻai aku he 304L a me 304 maʻamau ke hoʻololi ʻia, ʻo 304L ka koho maikaʻi loa no ka hoʻolōʻihi.ʻO L ke kalapona haʻahaʻa, e hāʻawi ana i ka 304L he 0.2% ka ikaika hua o 35 KSI, aʻo ka 304 he 0.2% ka ikaika hua o 42 KSI.Me ka 16% haʻahaʻa haʻahaʻa haʻahaʻa ikaika, 304L koi emi ikaika e deform a hoʻopaʻa i ka ʻeleʻele i ka wā o ke kaʻina hana.He maʻalahi ka hoʻohana.

Are you concerned about stamping in the shop or about tools and dies? If so, send your questions to kateb@thefabricator.com and Thomas Vacca, CTO of Micro Co., will answer them.

ʻO STAMPING Journal ʻo ia wale nō ka hoʻolaha kālepa i hoʻolaʻa wale ʻia i nā pono o ka mākeke stamping metal.Mai ka makahiki 1989, ua hoʻolaʻa ʻia ka paʻi ʻana i nā ʻenehana ʻokiʻoki, nā ʻano ʻoihana, nā hana maikaʻi loa a me nā nūhou e kōkua i nā ʻoihana stamping e holo pono i kā lākou ʻoihana.

Loaʻa ka loaʻa kikohoʻe piha i ka FABRICATOR i kēia manawa, e hāʻawi maʻalahi ana i nā kumuwaiwai waiwai waiwai.

Loaʻa ka loaʻa kikohoʻe piha i ka The Tube & Pipe Journal i kēia manawa, e hāʻawi maʻalahi ana i nā kumuwaiwai waiwai waiwai.

E hauʻoli i ke kiʻi kikohoʻe piha i ka STAMPING Journal, ka puke moʻolelo mākeke stamping metala me nā holomua ʻenehana hou loa, nā hana maikaʻi loa a me nā nūhou ʻoihana.

Loaʻa ka loaʻa piha ʻana i The Fabricator en Español digital edition, e hāʻawi maʻalahi ana i nā kumuwaiwai waiwai waiwai.

Ma ka ʻāpana mua o kā mākou ʻāpana ʻelua, ʻo ka mea pena metala a me ka welder ʻo Ray Ripple e hui pū me ka host Dan Davis…

Ka manawa hoʻouna: Jan-03-2023