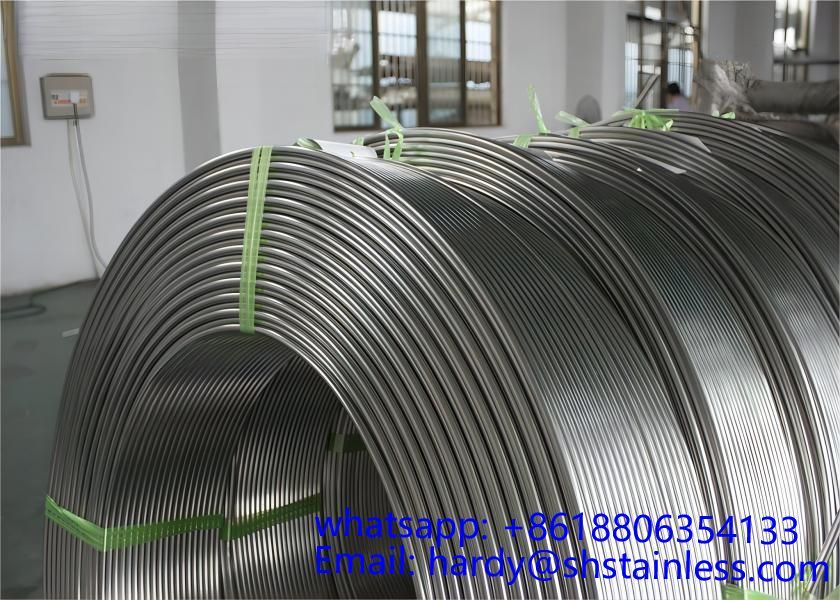

2507 kila kuhiliʻole 10*1mm coiled capillary paipu

OLELO HOOLAHA

2507 kila kuhiliʻole 10*1mm coiled capillary paipu

Hoʻokumu ʻia kā mākou mau mea super-duplex a pau e Norsok M-650 Ed.4 a me / a i ʻole nā mea hana kūpono ISO 17782.

ʻO Super Duplex UNS S32750 ka papa super duplex maʻamau i ka mākeke.ʻO UNS S32750 kahi duplex i hoʻolālā kūikawā ʻia no ka lawelawe ʻana i nā kaiapuni i loko o ka chloride.He kū'ē maikaʻi loa ia i ka corrosion localized a me ke koʻikoʻi corrosion māwae i hui pū ʻia me ka ikaika mechanical kiʻekiʻe.Hoʻohana nui ʻia ia i ka aila a me ke kinoea, hydropower, nā moku kaomi, pulp & pepa, nā mea hana a me nā tankers kemika.

Nā noi

2507 kila kuhiliʻole 10*1mm coiled capillary paipu

ʻO nā noi nui no nā kikoʻī me nā koi kūikawā no ke kūpaʻa corrosion kiʻekiʻe.

Hōʻike ʻia ka UNS S32750 e:

- Kūʻē kiʻekiʻe i ke koʻikoʻi ka pohā ʻana i ka halide i loko o nā kaiapuni.

- Kūleʻa kiʻekiʻe i ka lua a me ka crevice corrosion.

- Kūleʻa kiʻekiʻe i ka corrosion maʻamau.

- Ka ikaika mechanical kiʻekiʻe.

- ʻO ke kūpaʻa kiʻekiʻe i ka erosion corrosion a me ka corrosion fatigue.

Heat Treatment2507 kila kila 10*1mm coiled capillary paipu

ʻO ka hoʻoheheʻe ʻana i ka hopena ma kahi o 1100 ° C a ukali ʻia e ka hoʻopau ʻana i ka wai.

Weldability

Maikaʻi loa.

Hoʻohui Kimia (Kākoʻo no nā Bar)

| Kaumaha % | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | N | PRE |

| Min. | 24,0 | 6,00 | 3,00 | 0,24 | 41 | ||||||

| Max. | 0,030 | 1,20 | 0,025 | 0,010 | 0,80 | 26,0 | 8,00 | 4,50 | 0,50 | 0,32 |

PREN = % Cr + 3.3 % Mo + 16 % N ≥ 41

Nā Kūlana Kūlana

Nui:

- ʻO Norsok M-650 Ed.4 nā mea hana kūpono

- PED 2014/68/EU Annex I pauku 4.3

- AD2000 W0 (W2/W10)

- NACE MR0175/ ISO 15156-3 a me NACE MR0103/ISO 17945

- 2507 kila kuhiliʻole 10*1mm coiled capillary paipu

Papa, pepa a me ka wili:

- ASTM A240, EN 10028-7, EN 10088-2, EN 10088-4, Norsok M-630 MDS D55

Bar a me ka hana ʻana:

- ASTM A276, ASTM A479, ASTM A182, EN 10088-3, Norsok M-630 MDS D54/D57

Nā huahana ʻē aʻe:

- E like me nā kūlana ASTM a me / a i ʻole EN a me Norsok M-630 MDS

Nā Pono Mechanical (Maʻamau)

| Ka ikaika o ka hua Rp0.2, MPa | Ka ikaika tensile Rm, MPa | ʻO ka lōʻihi [%] | ʻoʻoleʻa [HB] | Ka hopena, Charpy-V, -46ºC [J] | |

| BAR | ≥ 550 | ≥ 750 | ≥ 25 | ≤ 300 | ≥ 65 |

| PULA CR (COIL) | ≥ 550 | 750 – 1000 | ≥ 25 | ≤ 310 | ≥ 45 |

| PLATE HR (COIL) | ≥ 550 | 750 – 1000 | ≥ 25 | ≤ 310 | ≥ 45 |

| PALAPALA (QUARTO) | ≥ 550 | 750 – 930 | ≥ 25 | ≤ 310 | ≥ 45 |