Alloy 625 Kuhiliʻole kila Coil Tubing Kumukuai

Ka Hui Kimia, %

Alloy 625 mea non-magnetic, austenitic, a hōʻike kiʻekiʻe tensile ikaika, fabricability, a me brazeability.Ma muli o kona kiʻekiʻe nickel maʻiʻo, ʻaneʻane pale ʻia kēia huila i ka chloride ion stress-corrosion cracking a me ka lua, ka mea maʻamau i loaʻa i nā metala i nā noi wai kai e like me nā mea hoʻololi wela, nā mea hoʻopaʻa, a me nā kaula kaula.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Koena | 8.0-10.0 | 1.0 ka nui | 3.15-4.15 | .40 ka nui | .40 ka nui | .10 ka nui |

| Fe | Mn | Si | P | S |

| 5.0 ka nui | .50 ka nui | .50 ka nui | .015 ka nui | .015 ka nui |

Ma nā polokalamu hea i hoʻohana ʻia ai ʻo Inconel 625?

- Hoʻohana nui ʻia ʻo Inconel 625 i ka ʻoihana Aerospace

- Nā ʻōnaehana hoʻoheheʻe mokulele

- Pūnaehana hoʻopau ʻenekini jet

- Pūnaehana hoʻohuli ʻenekini

- Mea hana wai kai kūikawā

- Mea hana kaʻina hana kemika

Nā kikoʻī o ka ASTM

| Paipu Smls | Pipe Weled | Tube Smls | Tube Weld | Pepa/Pula | Bar | Ke kalaiwa ana | Hoʻopili | Uea |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Na Waiwai Mechanical

| Ka mahana° F | U'a (psi) | .2% Hua (psi) | ʻO ka hoʻolōʻihi ʻia i 2 “(%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 Lae hehee

| Lae hehee | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 Kaulike

| KANAWAI | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

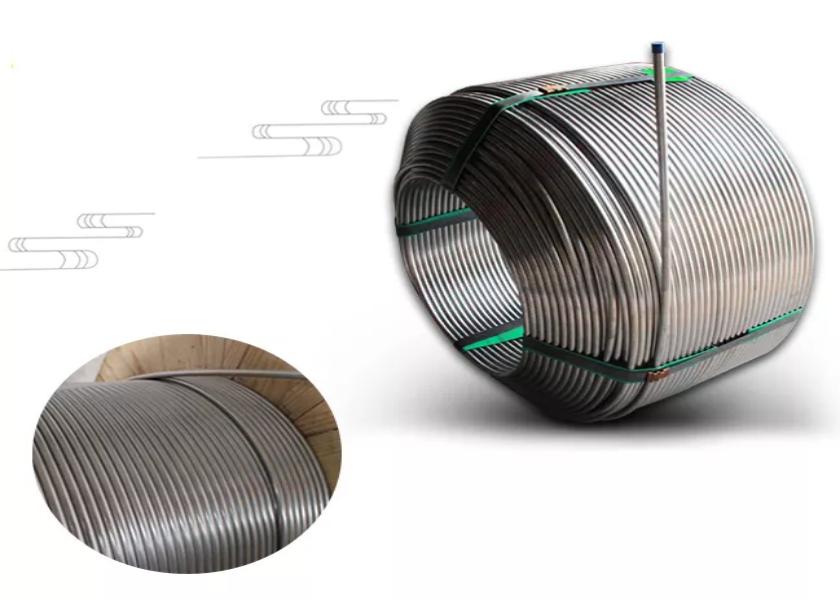

Huipuia 625 Tubing

ʻO Alloy 625 kahi austenitic nickel-chromium-molybdenum superalloy i ʻike ʻia no ke kūpaʻa ʻana i ka crevice corrosion a me ka oxidation ma nā wela kiʻekiʻe.Hiki ke loaʻa kēia mau mahana mai ka cryogenic a hiki i nā pae wela loa o 1,800°F.ʻO ka hana a me ka hoʻohui kemika o kēia papa e kūpono ia no nā noi nuklea a me ka aerospace.Eia kekahi, me ka hoʻohui ʻana o ka niobium, ʻike ʻia nā paipu alloy 625 iā ia iho me ka hoʻonui ʻana i ka ikaika me ka mālama wela.Hana kēia waiwai i ka papa i koho maikaʻi loa no ka hana ʻana.

Nā Kūlana Huahana

ASTM B444 / ASME SB444 / NACE MR0175

Lahi Nui

| Anawaena waho (OD) | Mānoanoa Pā |

| .375"–.750" | .035”–.095” |

Koi Kemika

Huina 625 (UNS N06625)

Huina %

| C Kalapona | Mn Manganese | Si Silika | P Phosphorous | Cr Chromium | Nb+Ta Niobium-Tantalum | Co ʻO ke kopa | Mo Molybdenum | Fe hao | Al Aluminum | Ti Titanium | Ni Nikela |

| 0.10 ka nui | 0.50 ka nui | 0.50 ka nui | 0.015 ka nui | 20.0–23.0 | 3.15–4.15 | 1.0 ka nui | 8.0–10.0 | 5.0 ka nui | 0.40 ka nui | 0.40 ka nui | 58.0 min |

Nā Manaʻo hoʻomanawanui

| OD | OD Hoomanawanui | Hoʻomanawanui pā |

| .375”–0.500” koe | +.004”/-.000” | ± 10% |

| 0.500”–1.250” koe | +.005”/-.000” | ± 10% |

Na Waiwai Mechanical

| Hua ikaika: | 60 ksi min |

| ʻOi aku ka ikaika: | 120 ksi min |

| Elongation (min 2"): | 30% |

Nā Kiʻi Factoy

Nānā

Hoʻouna a hoʻopili

Hoike Hoao